Locked rotor current calculations

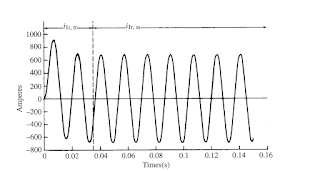

Locked rotor current as clear from its name is the current which motor must overcome for accelerating the motor. When motor is switched on motor isn’t turning and always draws maximum current. When motor starts accelerating this current goes down This locked rotor current is greater than full load current. This locked rotor current required to start the motor depend on the type of motor as well as the specified design voltage required for the motor, typically the higher the voltage, the lower the required amperage or current. Locked rotor current is 3-8 times the rated current of motor. "locked rotor current" is the current that would be drawn if the rotor were locked in place so it can't turn. At locked-rotor, each phase of an induction motor stator looks like a series R-L circuit. Locked rotor inrush current graph is as shown below:- Table for NEMA motors NEMA code letters for locked-rotor KVA/HP is below:- Let’s take an example of motor having motor rating of 30 H