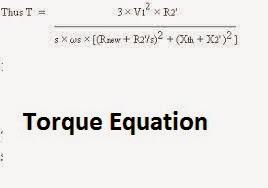

Induction Motors Torque Equation; Torque equation

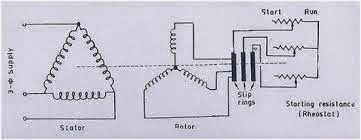

Torque equation for the Induction motor is as given below:- As we see from the above that Torque equation is Directly proportional to square of the voltage. Factors affecting the speed-torque characteristics of an Induction motor : The speed-torque characteristics are affected by various factors like applied voltage, R 2 ’ and frequency. (a) Applied voltage : We know that T µ V 2 . Thus not only the stationary torque but also the torque under running conditions changes with change in supply voltage. (b) Supply frequency : The major effect of change in supply frequency is on motor speed. The starting torque is reduced with increase in frequency. (c) Rotor resistance : The maximum torque produced does not depend on R 2 ’. However, with increase in R 2 ’, the starting torque increases. The slip at which T max is reached increases too which means that T max is obtained at lower motor speeds.