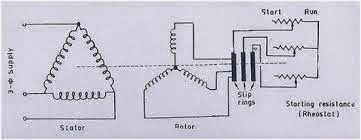

Slip Ring induction motors starting; Slip ring induction motor starter

Starting Of Slip Ring Induction Motors

Slip ring Induction motors had external resistance connected in line. These motors are usually started with full line voltage applied across its terminals. During starting of slip ring induction motors the value of starting current is adjusted or kept minimum, by increasing the resistance of the rotor circuit. The external resistance is connected in star and kept at maximum during starting so to minimize starting current. By increasing the rotor resistance it will not only reduces the rotor current but the stator current too.

This means that whenever a resistance is added in rotor circuit that will leads to reduced starting current. Thus because of this, the starting torque is increased due to the improvement in power factor.

Usually resistance is added during starting and slowly made out of circuit when motor attains the speed and this resistance is disconnected by using a contactor in line. Slip ring can be taken in line by using manually also. The 3-phase supply to the stator has a switching contactor along with over-load and no or low-voltage protective devices. There might be also an interlock provided to ensure the proper sequential operation of the control gear and starting devices.

Slip ring motors circuit diagram is as shown above.

Torque curve of Slip ring motors is shown above

As per torque formula

Torque is directly proportional to resistance.

So as the resistance is high in slip ring motors torque is also high during starting.

As these motors have considerably high starting torque with low starting current, these motors can be started on load. The external resistance is used only for the starting purpose, after which the motor gradually picks up the speed, the resistance gradually cut-off. These rings are isolated after the motor reaches its rated speed. The carbon brushes are lifted and the rings are short circuited thus making them very similar to squirrel cage motors.

Applications of Slip Ring Induction Motors

These motors are used where the load is intermittent and comes on very sharply for brief periods, such as a punching machine. A heavy flywheel is fitted in the drive, preferably between the work and any speed-reduction gears. The flywheel shares the load with the motor, thus enabling a motor of lower rating to be employed. For load sharing to take place automatically, the motor speed should drop considerably as the load increases and this is ensured by using a motor having a high full-load slip, say for example 10%.

Characteristics Of Slip Ring Induction Motor

As other induction motors consists of Stator and Rotor circuits slip ring motors also have same Stator circuit there is only difference in rotor circuit. Rotor circuit consists of external resistance in the circuit. The stator circuit is slip ring motors is rated as same in the squirrel cage motor, but the rotor is rated in frame voltage or short circuit current. The frame voltage is the open circuit voltage when the rotor is not rotating and gives the measure of turns ratio between the stator and rotor. The short circuit current is the current flowing when the motor is operating at full speed, with the slip rings shorted and the full load applied to the motor shaft.

Advantages of Slip-Ring Motors:

1. These are used where there are high Inertia loads as these motors have excellent starting torque.

2. These motors have low starting current then other induction motors.

3. It is easy to control the speed of the motor from 50% to 100% of the full speed,

Disadvantages of Slip Ring Motors

1. Higher brush and slip ring maintenance required,

2. As the brush wears out, it may lead to intermittent contact, and thus heavy sparking.

3. Also speed control of motor comes along with increased losses as heat comes across resistance.

Comments

Post a Comment