V/f control in Induction Motors; Volts per Hertz control

V/f control of Induction motors

V/f control is also known as volts per Hertz control. This method is the simplest method for motor control. In this control method there is not requirement of tuning . This type of control is used where there is requirement for operating the motor up-to 1000 HZ.

V/f control has some limitations that is weakness in starting torque and lack of control. By V/f method several motors can be started on single VFD which is not possible with encoder control. When several motors are connected on single VFD all motors can start and stop at same instant and also these motors will run same speed reference.

In V/f control method speed regulation is typically 2%-3%. Speed response in that type of control is 3 Hz. Speed response is how well the VFD responds to change in reference frequency. If this speed response increases then this means that motor will response quicker with the reference frequency change.

VFD speed control range in V/f control is in the range 1:40 . If we multiply this range with maximum frequency then this will determines the VFD’s minimum running speed at which it can control the motor. Lets take an example if rated frequency is 50 HZ then speed control will be 1:40X50= 1.25Hz.

There are two types of loads Variable torque loads and constant torque loads.

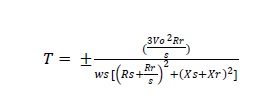

Torque formula for induction motors is as below:-

Torque speed characteristics for Induction Motors is as below:-

From above characteristics you will see that X-axis shows speed and slip while the Y-axis shows Torque and Current. When the motor is started, it draws very large current 6-7 times the rated current during starting, torque is around 1.5 times the rated torque of motor.

As motor speed increases current reduces slightly and then drops significantly when the speed reaches close to 80% of the rated speed. At the base speed, the rated current flows in the motor and rated torque is delivered.

At base speed, if the load is increased beyond the value for the rated torque, the speed drops and the slip increases. At a speed of 80% of the Synchronous speed, the load increases up to 2.5 times the rated torque, this is called the breakdown torque. Increasing the load further causes the torque to fall rapidly and the motor stalls

A variable torque V/f control will prevents faults and increases performance and efficiency of motors. In this control magnetizing current get reduced at low frequencies by lowering down the motor voltages at lower frequencies.

Torque speed curve for V/f control is as below:-

Now in constant torque applications need full magnetizing current at all speeds. So in this method straight slop is made and followed throughout the entire speed range.

There are various advantages of V/f control:-

(i) It provides wide range of speed.

(ii) This control will gives good running and Transient performance

(iii) Voltage and frequency reach rated value at base speed.

(iv) This is cheap and easy wiring

(v) This has low starting current requirements

Normal duty VFD Vs heavy duty VFD

There is thumb rule that Normal duty VFD’s are used for variable torque applications and Heavy duty VFD’s are used for constant torque applications.

This doesn’t imply that Normal duty VFD’s can’t be used for constant torque applications. Normal duty VFD’s can be used for Heavy duty applications but motor rating should be needed to be reduced, if there is VFD of 20 KW for normal duty than for heavy duty it will get reduced 15 KW.

In Normal duty VFD’s has specifications of overload for 110% for 60 Sec’s

And heavy duty VFD’s has specification of overload for 150% f0r 60 sec’s.

Normal duty VFD’s have higher continuous current rating than Heavy duty VFD’s.

Comments

Post a Comment